Golf iron made with the technology for precision molding.

New dimensional ideas, processes and specifications change the common sense of golf irons.

New dimensional ideas, processes and specifications change the common sense of golf irons.

1

Suitable for modern players

Golf iron in the form of a new dimensional concept

Golf iron in the form of a new dimensional concept

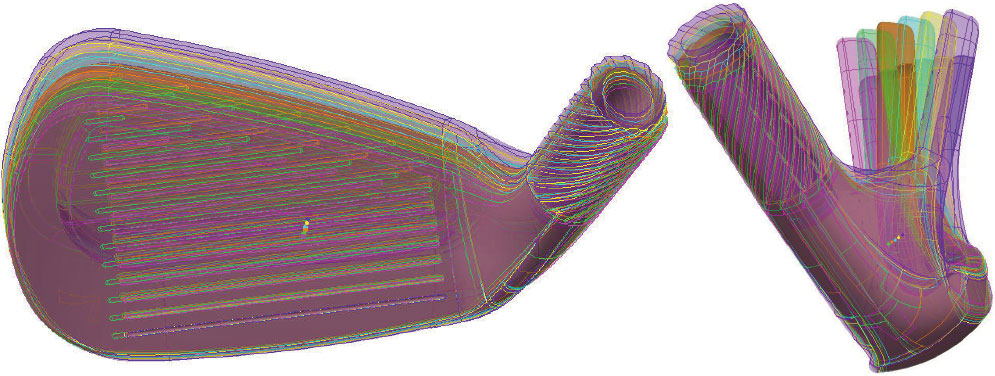

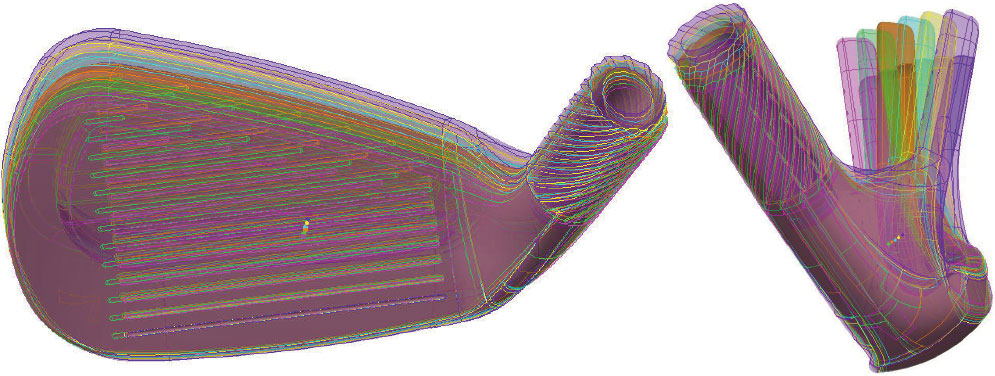

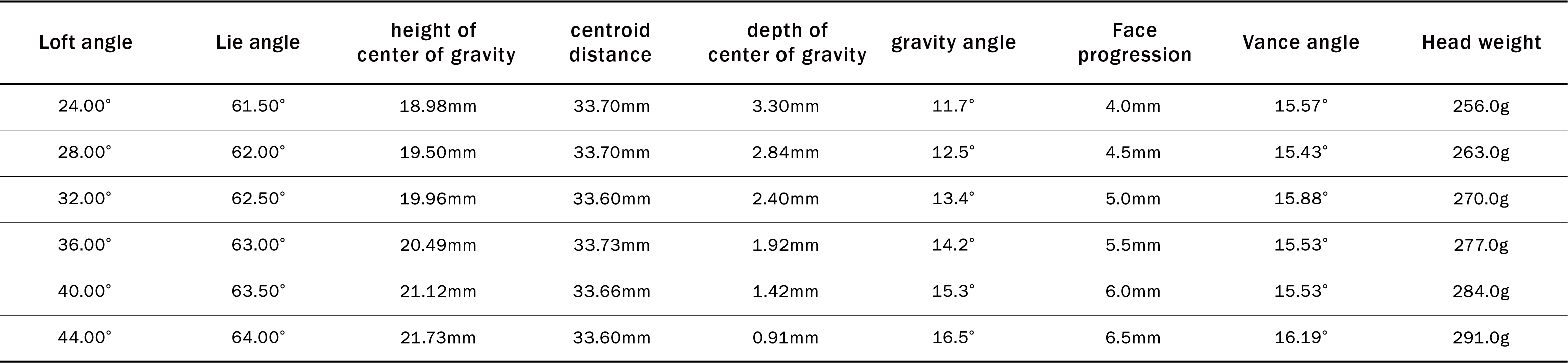

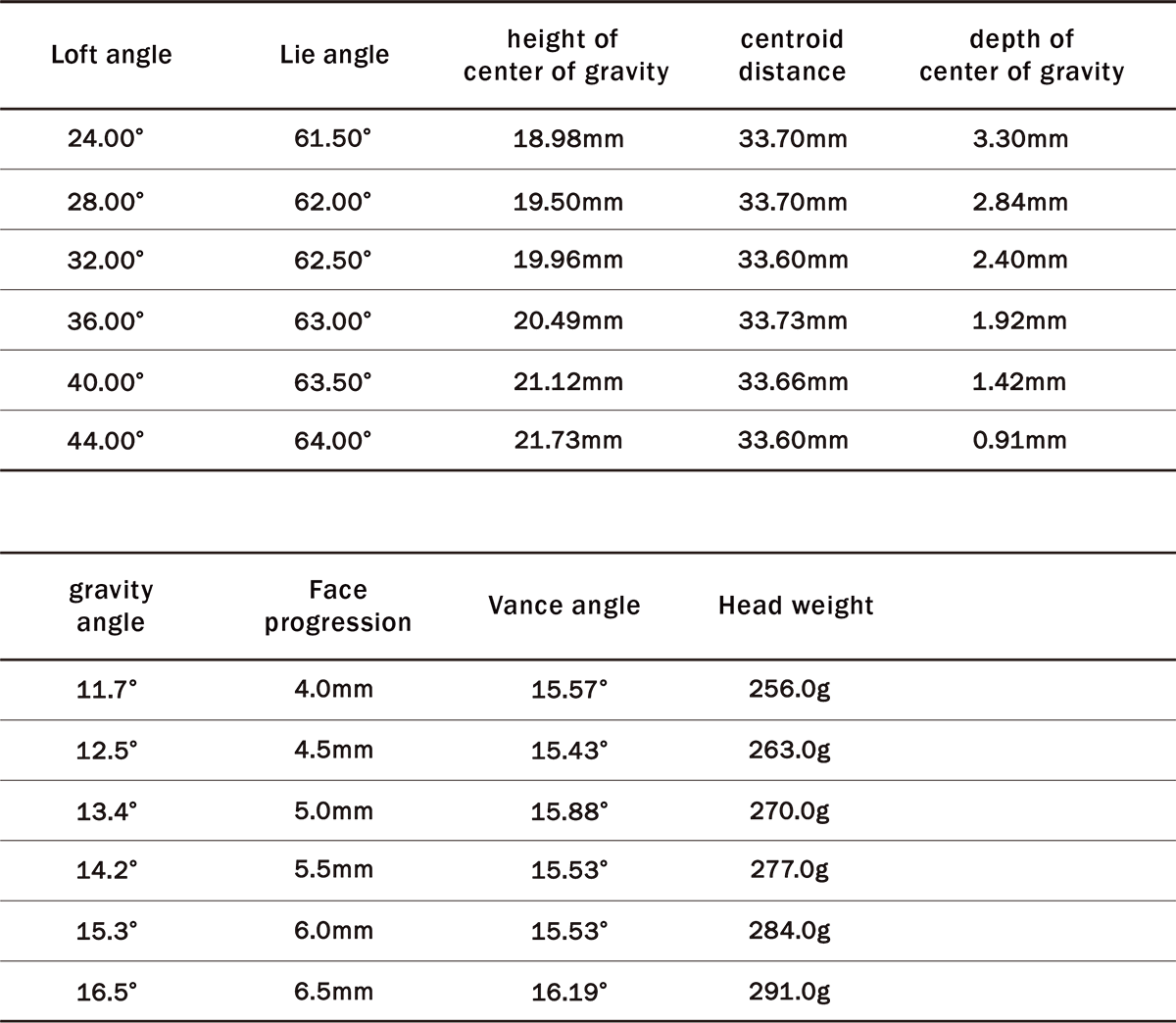

MUQU is made to match the player which is a whole new concept. It is common to change the position of the ball and the swing depending on the number of the iron, but in recent years it has become mainstream to hit the ball with the same swing regardless of the number. For each specific player, MUQU closely controlled all numerical values at the design stage, and maintain the height of the center of gravity made the center of gravity distance constantly. This makes it possible to fly the ball according to the angle of the count while keeping the position as designed. And thanks to the technology of the 5-axis CNC which machine-cuts the head which does not differ from the design.

2

Golf balls fly as your swing

New standards of iron heads

New standards of iron heads

With the 5-axis machining center cutting out, the plane accuracy of the head has reached a different dimension from human hand grinding. For this reason, the ground contact surface increases while impact, and the force is transmitted to the ball 100%. There will be no extra spinning. In theory, the trace of the golf ball should fly as your swing. And it is also highly possible to make a same swing. In other words MUQU is a standard golf iron that could measure the completeness of the player's swing. It would help you understand and improve your swing.

3

Inspired by molding technology

Mass production of the ideal form of golf irons

Mass production of the ideal form of golf irons

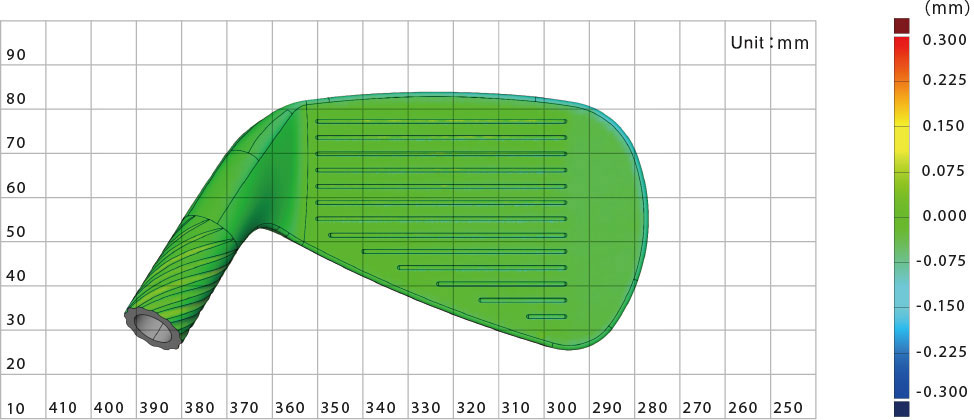

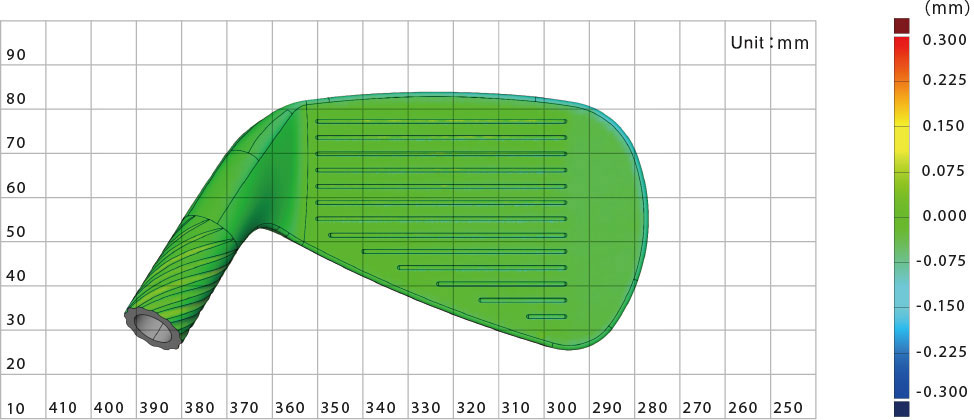

MUQU is designed by 3D CAD, and is cut out by 5-axis machining that can give an accuracy of 0.01 mm. A manufacturing method different from forged or lost wax process. The Manufacturer MS Seisakusho Co., Ltd., has been highly evaluated in the automotive industry for its technology for manufacturing molds. Produced golf irons with the ability to calculate even the subtle distortion of iron due to processing. Conventional clubs always require manual processing. Therefore, it would be impossible to make identical golf clubs. However, MUQU is made by machining center only, so if you make ten, you will get ten identical iron heads.

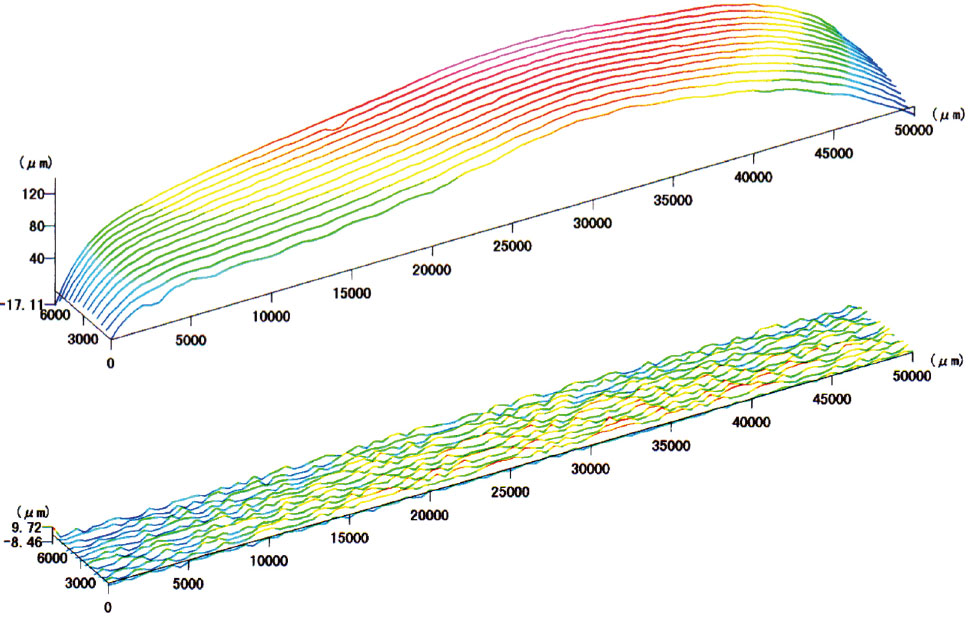

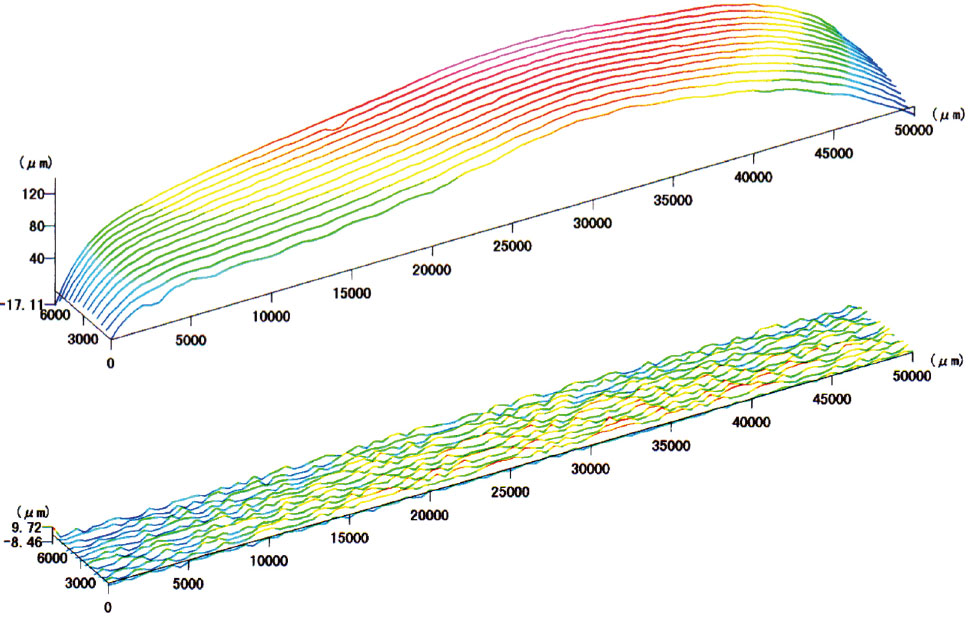

3-D measurement result: The actual goods are consistent with the design.

4

Brought to you by Craftsmen who know steel well To feel 3 different types of swinging and hitting of 3 kinds material

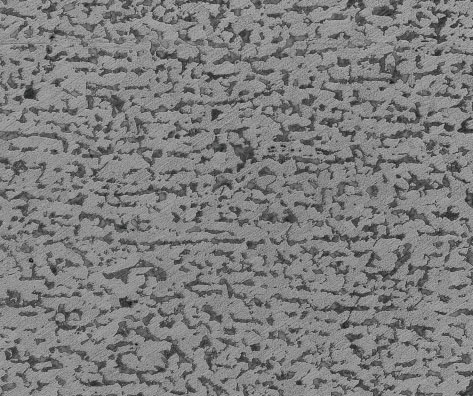

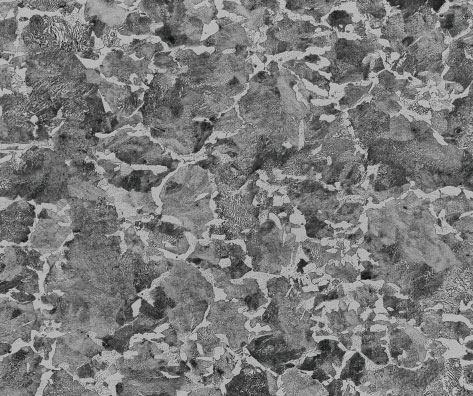

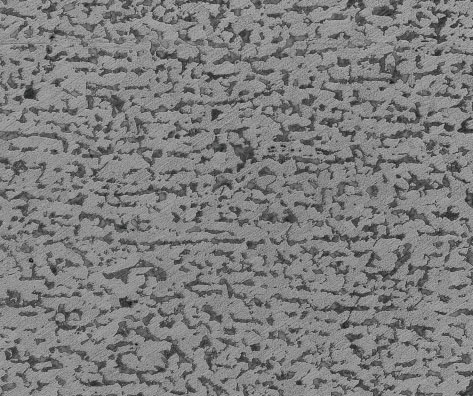

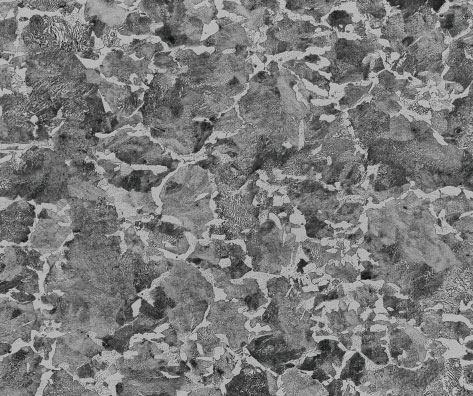

Preferences of the feeling of hitting are different. MUQU prepared three kinds of materials. Soft iron "S25C" often used in golf clubs. Hard "S50C", which has a high carbon content and has the nickname "steel". Stainless steel called "SUS303" which is not used in conventional iron. The original hardness of the material is utilized fully by CNC. If you look at it with a microscope, you can see the beautiful iron structure as shown in the picture. Each has a distinctly different feel. You can choose the best feeling for yourself.

Forging products

MUQU

5

Expressed muscle back in the cavity

Simple and innovative design

Simple and innovative design

The back face is finished in a pure and beautiful simple design. A new idea was also included in this simplicity. "We expressed muscle back in the cavity," says the designer. The shape of the undercut that can be achieved with 5-axis machining. By cutting diagonally, I left a thick part and made the hit feel firm. A new design that can be called just functional beauty.

6

Masters of different fields

Iron that detailed in every particular

Iron that detailed in every particular

Not only MS Seisakusho, various skills of manufacturing craftsmen are gathered for MUQU. The head plating process is carried out by Nagoya Plating Co., Ltd. A company that pursuing micron-level precision in surface treatment.

Official web site of Nagoya Plating Co., Ltd.:

www.nagoya-mekki.com

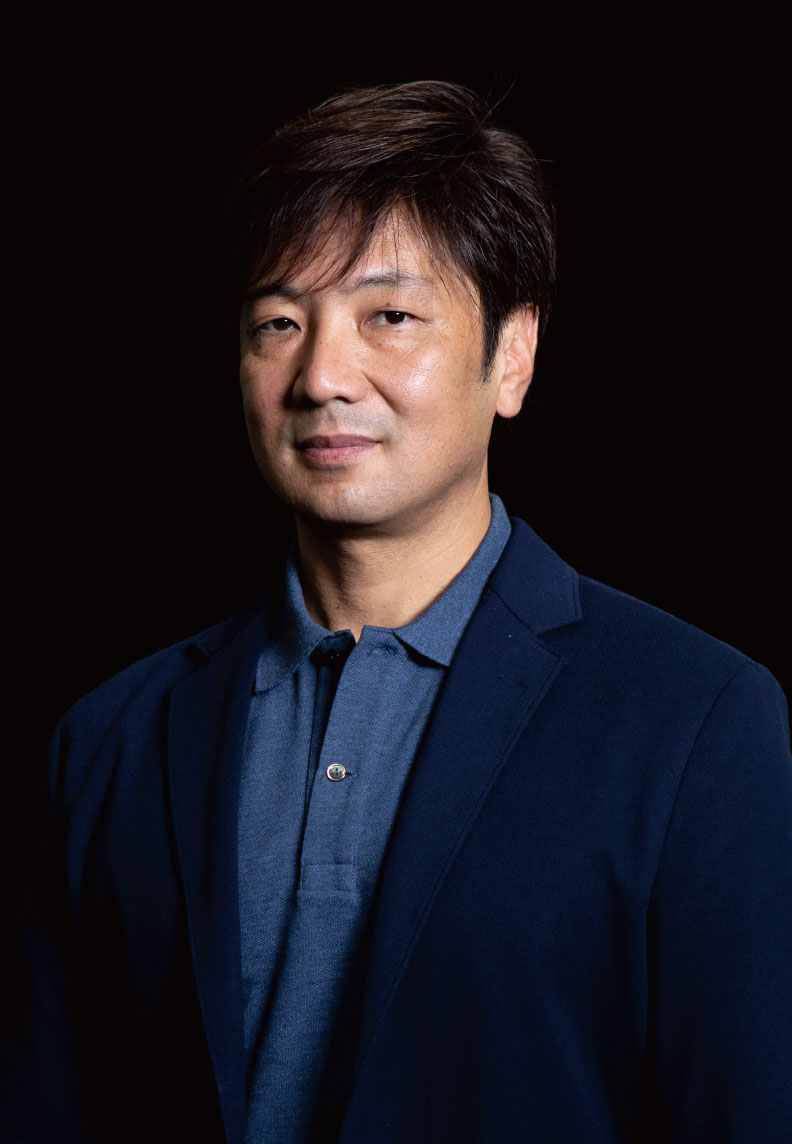

Designing・Supervision

IKUO SUZUKI / MEVAERU Co., Ltd.

/ MEVAERU Co., Ltd.

Born in 1971 in Toyoyama-cho, Aichi Prefecture. He has been involved in club development and promotion since 1997, hoping to help players to bring them more joy in golf. In 2001, he launched his own golf brand "ZONE" by making use of his past experience. The golf club has been favored by professionals and top amateurs. He is also in charge of the wedge design and adjustment of Yokohama Sakura and Rikako Morita in their amateur age. In 2009, "MEVAERU Co., Ltd." was established. In charge of the design and design of MUQU.